Audi FAW NEV Company, a partnership between Audi and FAW, has commenced production of fully electric Audi models at its state-of-the-art facility in Changchun, China. The plant exclusively manufactures electric vehicles based on Audi’s Premium Platform Electric (PPE), marking a significant milestone in the brand’s electrification strategy for the Chinese market.

The facility launched production with the Audi Q6L e-tron family, including the Q6L Sportback e-tron, and plans to follow with a market-specific version of the Audi A6 e-tron. These models, tailored to Chinese consumers, incorporate design innovations like extended wheelbases and advanced digital experiences.

“This new facility reinforces our commitment to the Chinese market and represents a pivotal step in our electrification journey,” said Gernot Döllner, CEO of AUDI AG.

Cutting-Edge Technology and Sustainability

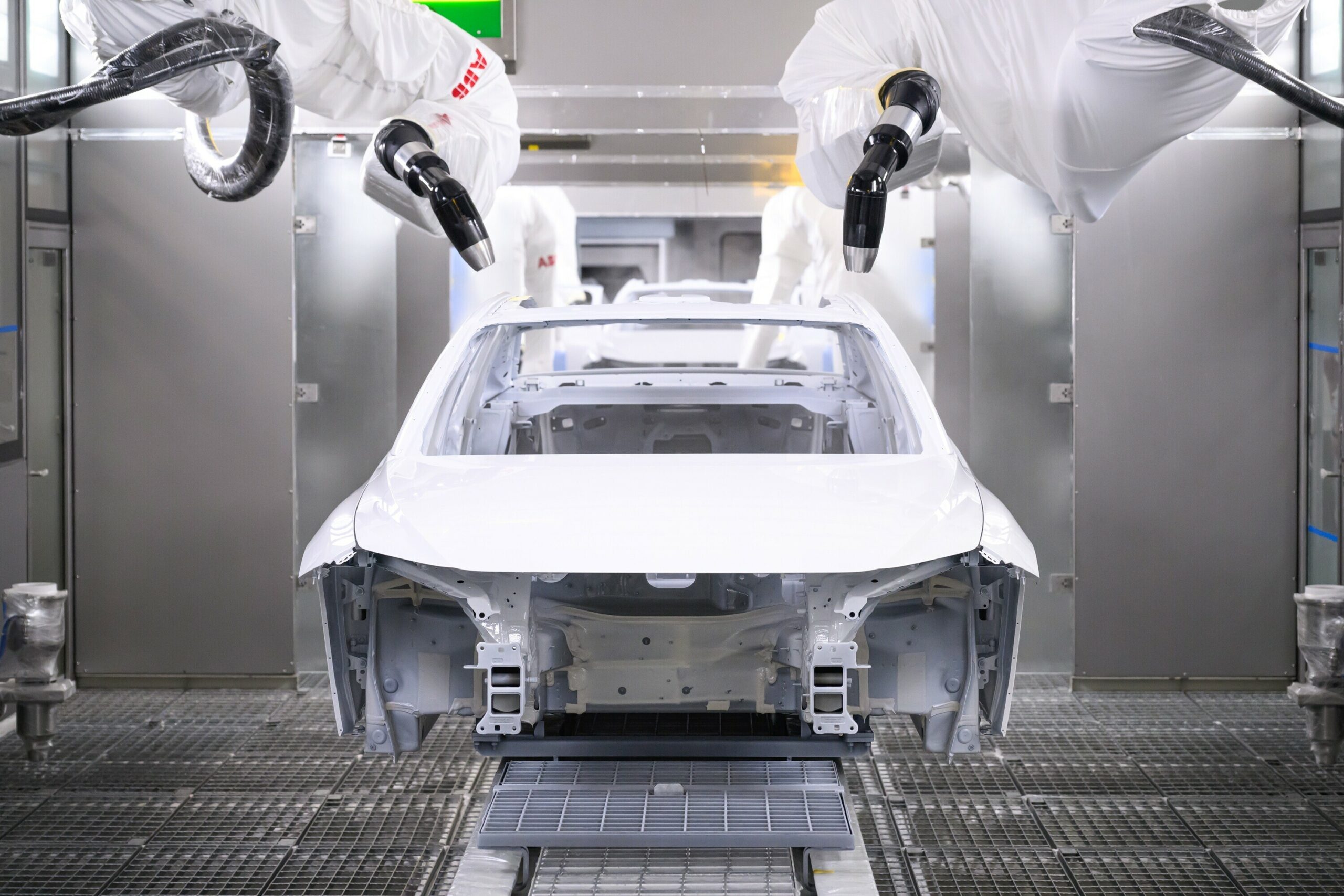

The Changchun plant employs advanced digital technologies, including digital twinning and a cloud-based IT architecture powered by SAP S/4HANA. Over 800 robots, driverless transport systems, and an automated warehouse optimize production efficiency. Audi is also exploring humanoid robotics in collaboration with Chinese innovation centers.

Sustainability is a core focus, with the plant operating on green energy and striving for net carbon neutrality by 2025. Solar panels, biomass energy, closed-loop wastewater systems, and recycling initiatives underpin its “Mission:Zero” environmental program. Biodiversity measures, including wetland creation and bee habitats, enhance ecological harmony.

Local Integration and Supply Chain Optimization

Around 3,000 jobs will be created at the facility, which has a production capacity of 150,000 vehicles annually. To support operations, 50% of suppliers are located within 30 kilometers of the site, aligning with Audi’s “in China, for China” strategy. A dedicated supplier park established by the local government further enhances logistics efficiency.

The Changchun plant demonstrates Audi’s commitment to electrification, sustainability, and market-specific innovation in China. With its cutting-edge operations and focus on local integration, the facility sets new standards for eco-friendly automotive production.